Main Products and Common Welding Consumables

Our company is a construction and engineering unit specializing in the fabrication of chemical and petrochemical equipment, boilers, storage tanks, towers, pipelines, and structural components. Due to the nature of construction projects, the most commonly used welding methods include shielded metal arc welding (SMAW), tungsten inert gas (TIG) welding, gas metal arc welding (GMAW), submerged arc welding (SAW), and electro-slag vertical welding. As a result, the primary welding materials used are welding electrodes, solid wires, and flux-cored wires. The materials involved are diverse, including heat-resistant steels like chrome-molybdenum, low-temperature steels, stainless steels, nickel alloys, titanium alloys, and aluminum alloys. Currently, SMAW and TIG welding are widely used due to their flexibility and high penetration in the field. However, GMAW, SAW, and electro-slag welding are limited by various conditions, resulting in restricted applications. According to incomplete statistics, welding rods account for over 50% of the total welding material usage, while GMAW wires make up less than 30%, with the rest covering other methods.

Experimental Application of P91 Heat-Resistant Steel Solid Wire in Gas Shielded Welding

With the advancement of welding technology, gas shielded welding and submerged arc welding are gradually being adopted on construction sites, such as in alloy pipeline welding and transverse submerged arc welding in tank projects. Among these, martensitic heat-resistant steel T/P91 is widely used in high-pressure and high-temperature environments, replacing older grades like T/P22 and T/P5 in refineries and distillation units. However, its welding performance is poor, often leading to issues like cold cracking, brittle welds, and softening in the heat-affected zone (HAZ). To achieve satisfactory welds, strict adherence to technical guidelines is necessary. The conventional method involves TIG welding for the root pass, followed by SMAW for filling and capping, with most materials still imported.

Given that P91 materials are typically thick-walled, the low-efficiency SMAW process struggles to meet the demands of fast-paced construction projects. In response, our company has focused on developing high-efficiency welding processes and materials for P91 pipelines, including gas shielded and submerged arc welding.

To this end, we collaborated with welding consumables manufacturers and conducted extensive tests on P91 solid wire in gas shielded welding. After several trials, we tested different gas mixtures using P91MIG solid wire.

First, using 100% argon resulted in unstable arcs, shallow penetration, and poor fusion between the molten pool and base metal.

Second, a 95% Ar + 5% COâ‚‚ mixture improved arc stability slightly but still led to shallow penetration and difficult operation.

Third, an 85% Ar + 15% COâ‚‚ mixture provided better arc stability, good weld formation, and improved surface quality, but penetration was still insufficient for full automatic welding.

Finally, we determined that a gas mixture of 80% Ar + 20% COâ‚‚ produced stable arcs, adequate penetration, and good fusion. This allowed both manual and automatic welding operations.

Key aspects of the welding process include maintaining thin layers (≤3mm), ensuring proper side-to-side pauses and full filling to prevent unfused defects. Wind protection is essential to avoid porosity caused by air movement. Heat input must be strictly controlled: ≤15 kJ for TIG and ≤30 kJ for GMAW. Interpass temperature should remain between 210–230°C, and post-weld cooling should be gradual, followed by post-heating at 350°C for one hour.

The test weld joints were evaluated according to relevant standards, passing normal temperature bending, tensile, and impact tests. Additional high-temperature tensile and creep tests were also conducted, with all results meeting specifications. Based on these findings, two welding procedures were established. Building on the success of P91 GMAW, we are now conducting tests on submerged arc welding to meet future P91 pipeline welding needs.

Future Development Ideas for Welding Materials

Modern refining and chemical engineering projects involve large-scale structures, containers, and pipelines, with increasing demands for high-temperature, high-pressure, and corrosion-resistant materials. The use of advanced alloys like heat-resistant steels, low-temperature steels, stainless steels, duplex steels, and non-ferrous metals is growing, making material selection more complex. These trends require more efficient, environmentally friendly, and user-friendly welding processes and materials.

(1) For steel structures, reducing the inefficiency and high cost of SMAW is crucial. While GMAW or self-shielded welding offers better alternatives, they currently lack field adaptability and ease of operation. Improving welding material performance can enhance welder usability and reduce costs. Self-shielded wires offer local production potential and could open up significant market opportunities.

(2) In piping systems, submerged arc welding offers high efficiency and good welder operability during factory prefabrication. However, challenges arise with special materials like P91 and 9% Ni steel, where current submerged arc welding wires and fluxes are not fully developed, limiting their application.

(3) With the growing demand for deep chemical processing, non-ferrous metals like titanium, aluminum, and nickel alloys are increasingly used. However, their welding methods and materials are still limited—nickel alloy GMAW wires are not localized, and domestic aluminum welding wires have unstable quality. Titanium welding is mainly done via TIG, highlighting the need for further R&D to improve quality and efficiency.

More exciting content Welcome to Metalworking Online》》》Essen Special Report

The 19th Beijing Essen Welding & Cutting Fair

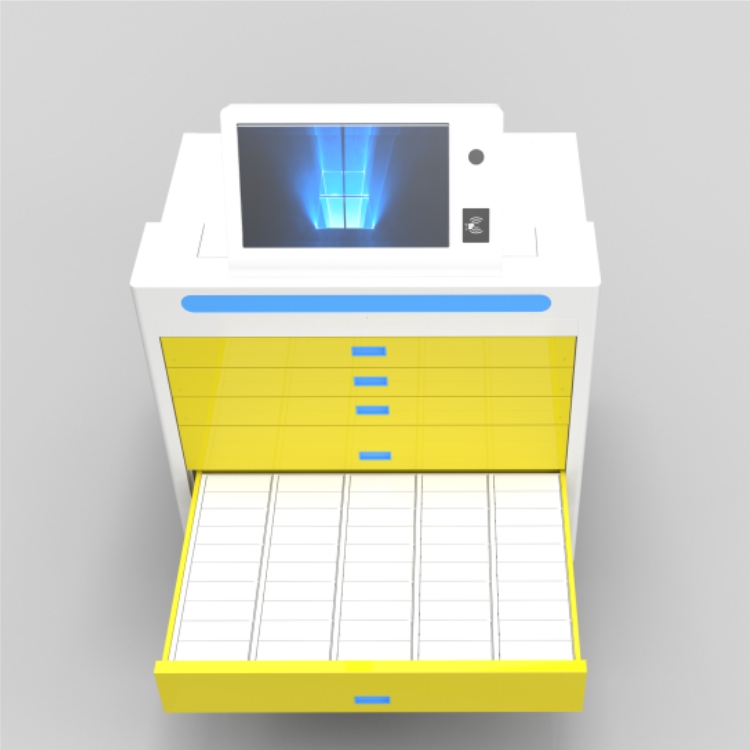

Intelligent Drawer Cabinet

Jiangsu XC Intelligent Technology Co., Ltd. is a pioneer in the field of industrial segmentation, a comprehensive solution provider that integrates software and hardware development, industrial digital intelligence, and industrial cost reduction and efficiency improvement.Intelligent tool cabinet, Intelligent Material Cabinet, intelligent tool cabinet, intelligent shelf, intelligent Stereoscopic warehouse, AGV intelligent forklift, AGV intelligent handling robot, MES system development, ERP system development, SaaS system development, etc.

Widely used in the automotive industry, mold manufacturing, engineering machinery, power generation equipment, precision machinery High end manufacturing sectors such as aerospace and healthcare.Product weight: 250KG

Dimension: 1050mm long; 502mm thick; 1600mm high

Grid size: 135mm long; 58mm wide; 50mm high

Screen size: 21.5-inch touch screen

Product color: White yellow (customizable)

Capacity: 462 grids

Freight lane type: 11 floors * 6 lanes * 7 grids

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ

Intelligent smart cabinet,Drawer Tool Cabinet,Drawer Storage Cabinet,Drawer Tool Storage Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com